A dry strength agent helps you improve the mechanical strength and quality of paper during manufacturing. When you add this chemical additive to cellulose fibers, you increase internal bonding, making the paper more resistant to tearing and bursting. Natural agents like starch offer eco-friendly benefits, while synthetic polymers deliver high durability for demanding applications.

The use of dry strength agents supports sustainability by reducing fiber consumption and improving recyclability.

| Market Segment | Market Size (USD Billion) | Year | Forecast Market Size (USD Billion) | Forecast Year | CAGR (%) |

|---|---|---|---|---|---|

|

Overall Paper Dry Strength Agents Market |

1.2 |

2024 |

1.8 |

2033 |

5.2 (2026-2033) |

|

Polyacrylamide Paper Dry Strength Agent |

2.1 |

2023 |

3.8 |

2032 |

6.1 |

|

Starch Based Polymers Paper Dry Strength Agent |

1.2 |

2024 |

2.5 |

2033 |

8.5 (2026-2033) |

- Natural and synthetic agents both enhance tensile, burst, and tear resistance.

- Advances in biotechnology and chemical formulations continue to boost efficiency and sustainability.

Key Takeaways

- Dry strength agents improve paper strength by bonding cellulose fibers, making paper more durable and resistant to tearing.

- Natural agents like starch offer eco-friendly benefits, while synthetic polymers provide higher strength and consistent performance.

- Using dry strength agents helps reduce fiber use, lowers production costs, and supports sustainability by improving recyclability.

- Proper dosage and application of dry strength agents are crucial to balance strength, flexibility, and paper quality.

- Choosing the right agent depends on your paper type, fiber quality, and environmental goals to achieve the best results.

Dry Strength Agent Basics

What Is a Dry Strength Agent

You encounter a dry strength agent as a specialized chemical additive in papermaking. This agent improves the mechanical strength of paper when dry. Chemically, you find that these agents are polymers or resins, such as cationic starch and polyacrylamide derivatives. Their molecular structure and ionic properties allow them to form strong bonds between cellulose fibers. You often see these agents working with aluminum ions to enhance the dry mechanical properties of paper. Over time, the industry has shifted from natural materials like rosin and alum to advanced synthetic polymers and modified natural polymers. For example, cationic starch, a positively charged modified starch, interacts efficiently with negatively charged cellulose fibers. This interaction increases the durability and tear resistance of the final paper product.

When you look at commercial dry strength agents, you notice several primary components:

- Water-soluble polyelectrolytes

- Anionic copolymers of acrylamide

- Amphoteric acrylamide polymers (with both anionic and cationic groups)

- Cationic starch (especially common in North America)

- Natural derivatives such as carboxymethyl cellulose and guar gum derivatives

These components work together to enhance the bonding and strength between paper fibers, fulfilling the essential role of a dry strength agent in the papermaking process.

Main Functions

You rely on dry strength agents to improve the strength and durability of paper under dry conditions. These agents enhance internal bonding between cellulose fibers, which directly increases the tensile strength, tear resistance, and stiffness of the paper. You also see improvements in overall paper quality. Different types of dry strength agents serve specific purposes. For instance, cationic starch boosts strength and stiffness in printing and writing papers. Polyacrylamide increases tensile, burst, and tear strength in packaging papers. Carboxymethyl cellulose improves both wet and dry strength, softness, and absorbency in tissue products.

Tip: By using dry strength agents, you can reduce pulp usage, which leads to cost savings and supports sustainability goals.

The main functions of dry strength agents in papermaking include:

- Improving internal bonding between cellulose fibers.

- Increasing tensile strength, tear resistance, and stiffness.

- Enhancing overall paper quality and machine runnability.

- Allowing the use of lower grammage paper, which saves fiber and energy.

- Reducing refining energy and dust generation.

- Lowering the consumption of other chemicals, such as wet strength resins and retention polymers.

- Supporting the substitution of cheaper fibers or fillers without sacrificing quality.

You can see the benefits of increased dry strength in the following table:

| Strength Types Improved | Benefits of Increased Dry Strength |

|---|---|

|

Tensile |

Enables production of lower grammage paper, saving fiber and energy |

|

Burst |

Reduces refining energy and dust generation |

|

Compression (SCT, RCT, etc.) |

Lowers chemical consumption (wet strength resins, starch, retention polymers) |

|

Stiffness |

Allows substitution with cheaper fibers or fillers |

|

Internal (Scott bond) |

Improves machine runnability and converting efficiency |

|

Surface (lint or dust reduction) |

Increases productivity and dewatering |

You must balance the dosage of dry strength agents, as excessive use can negatively affect flexibility and stiffness. The right choice and application of these agents help you achieve the desired paper properties while maintaining cost efficiency and sustainability.

How Dry Strength Agents Work

Fiber Bonding Mechanism

When you add a dry strength agent to the papermaking process, you introduce a powerful tool for reinforcing the bonds between cellulose fibers. These agents, such as cationic starch and polyacrylamide, anchor themselves onto the surfaces of cellulose fibers through electrostatic attraction. The positively charged groups on these polymers are drawn to the negatively charged cellulose, creating a strong initial attachment. This process increases the contact area between fibers and promotes physical entanglement, which is essential for robust sheet formation.

You benefit from several key mechanisms when using a dry strength agent:

- The agent adsorbs onto fiber surfaces, increasing the potential for hydrogen bonding.

- Hydrophilic polyelectrolytes with high molecular weight promote inter-fiber bonding.

- Polyelectrolyte complexes sometimes form on fiber surfaces, leading to even greater strength.

- The increased contact area and improved fiber entanglement result in stronger paper sheets.

Note: Unlike wet strength agents, which rely on covalent crosslinking to maintain strength in wet conditions, dry strength agents focus on enhancing natural fiber bonding in the dry state.

Experimental studies confirm that the main improvement in paper strength comes from increased inter-fiber bonding. The strength of individual cellulose fibers already exceeds that of the paper sheet, so reinforcing the bonds between fibers is crucial. You can observe this effect through higher tensile strength, burst resistance, and improved sheet consolidation during drying. Advanced imaging techniques, such as confocal laser scanning microscopy, show that these polymers deposit primarily on fiber surfaces and at fiber-fiber junctions, reinforcing the network and boosting mechanical properties.

Hydrogen Bonding Role

Hydrogen bonding plays a significant role in the papermaking process. When you use a dry strength agent, you enhance the potential for hydrogen bonds to form between cellulose fibers. The agent’s molecular structure and charge density influence how effectively it can promote these bonds. Cationic starch, for example, is engineered with tertiary amines to maximize electrostatic attraction and hydrogen bonding with cellulose.

Colloidal probe microscopy reveals that cationic polymers interact with cellulose through both electrostatic forces and hydrogen bonds. These interactions stabilize the fiber network and contribute to the overall strength of the paper. However, the quantitative impact of hydrogen bonding on tensile strength is limited. Hydrogen bonds contribute a measurable amount of bonding energy, but the introduction of a dry strength agent can increase the total bonding energy by up to 87 times, mainly through enhanced Coulombic (electrostatic) interactions.

| Bonding Type | Relative Contribution to Strength | Mechanism |

|---|---|---|

|

Hydrogen Bonding |

Moderate |

Attraction between polar groups |

|

Coulombic Bonding |

High (with dry strength agent) |

Electrostatic attraction (cationic/anionic) |

|

Covalent Bonding |

Low (for dry strength agents) |

Not typical for dry strength agents |

You should remember that while hydrogen bonding is important, the real strength boost comes from the combined effect of hydrogen and electrostatic interactions. The dry strength agent acts as a bridge, bringing fibers closer and allowing more bonds to form, which leads to stronger, more durable paper.

Types of Dry Strength Agents

Natural Polymers

You often choose natural polymers when you want to prioritize sustainability and environmental safety in papermaking. Starch and its modified forms, such as cationic and anionic starch, are the most widely used natural dry strength agents. These polymers contain many polyhydroxyl groups, which form hydrogen bonds with cellulose fibers. This action increases fiber bonding and improves the tensile and bursting strength of your paper. Guar gum also serves as a natural dry strength additive, offering similar benefits.

- Starch

- Guar gum

These natural agents are renewable, biodegradable, and eco-friendly. You find them especially useful in applications where recyclability and biocompatibility matter, such as food packaging. However, you may notice that natural agents sometimes have performance limitations compared to synthetic alternatives. Research continues to improve their effectiveness, but production costs remain higher due to natural sourcing and processing.

Tip: If your goal is to meet strict environmental regulations or appeal to eco-conscious consumers, natural polymers provide a strong foundation for sustainable papermaking.

Synthetic Polymers

You turn to synthetic polymers when your application demands high mechanical strength and consistent performance. Polyacrylamide and polyvinylamine are common synthetic dry strength agents. These agents deliver excellent binding capabilities, increasing the tensile strength and stiffness of your paper. Industries such as packaging and specialty paper production often prefer synthetic agents because they maintain superior strength under a wide range of conditions.

Synthetic polymers offer several advantages:

- High mechanical strength and thermal stability

- Highly tunable properties for specific needs

- Consistent quality and easy processing

- Lower production costs

However, you should consider that synthetic agents lack intrinsic bioactivity and biodegradability. They may require chemical modification for certain applications.

| Aspect | Synthetic Polymers | Natural Polymers |

|---|---|---|

|

Mechanical Strength |

High |

Moderate |

|

Tunability |

Highly tunable |

Limited |

|

Consistency |

Excellent batch-to-batch |

Variable |

|

Biodegradability |

Low |

High |

|

Cost |

Lower |

Higher |

You must weigh your priorities—whether you value sustainability or need maximum strength—when selecting the right dry strength agent for your process.

Benefits and Applications

Strength Improvement

You can achieve significant gains in paper strength by using modern additives. Scientific studies show that polymers such as starch and synthetic agents like polyacrylamide improve the bonding within the paper matrix. This stronger bonding increases tensile strength, burst strength, and folding endurance. When you add long man-made fibers to pulp, you reinforce weak spots in the paper structure. This approach improves resistance to rupture and increases elongation. As a result, you produce paper that is both stronger and more flexible. These improvements allow you to create lighter paper products without sacrificing durability. You also see better runnability and production speed on your machines.

Efficiency and Sustainability

You benefit from greater efficiency and sustainability when you use the right dry strength agent. These additives help you optimize fiber binding, especially when you work with recycled fibers or face challenging conditions. You can reduce the need for other chemicals, such as foam control agents and retention aids. For example, using 1.5 pounds of a modern agent per ton can match or exceed the performance of 2.5 pounds of traditional resin, saving you steam and other resources. This efficiency leads to cost savings and supports your sustainability goals.

- You use less raw material, water, and energy, which reduces waste and environmental impact.

- You improve the recyclability of paper, supporting a circular economy.

- You can produce lightweight, strong packaging that replaces plastics and meets market demand for sustainable products.

Tip: Choosing bio-based or biodegradable agents helps you meet environmental regulations and appeal to eco-conscious customers.

Application Methods

You have several effective ways to apply these agents in industrial papermaking. Research shows that water-soluble amphoteric polyacrylamide works well, especially for recycled fibers. At a 0.5% dosage, it can improve breaking length by up to 80% for recycled fibers. Chemically modified cornstarch also offers strong results, especially for pulps with high water retention and short fibers. You do not need special equipment for these agents, making them easy to use.

The method of application affects performance. You should pay attention to concentration, order of addition, and polymer structure. The table below summarizes key factors:

| Factor | Best Practice | Effect on Strength |

|---|---|---|

|

Concentration |

Higher tensile and burst |

|

|

Order of Addition |

Follow recommended sequence |

Maximizes performance |

|

Polymer Structure |

Choose branched anionic resins |

Higher dry strength |

|

Preparation Conditions |

Use low temperature and correct ratios |

Stable, effective product |

You typically use dosages between 0.01% and 2% by weight of active polymer. By controlling these variables, you ensure the best possible improvement in paper strength and quality.

Practical Considerations

Dosage and Compatibility

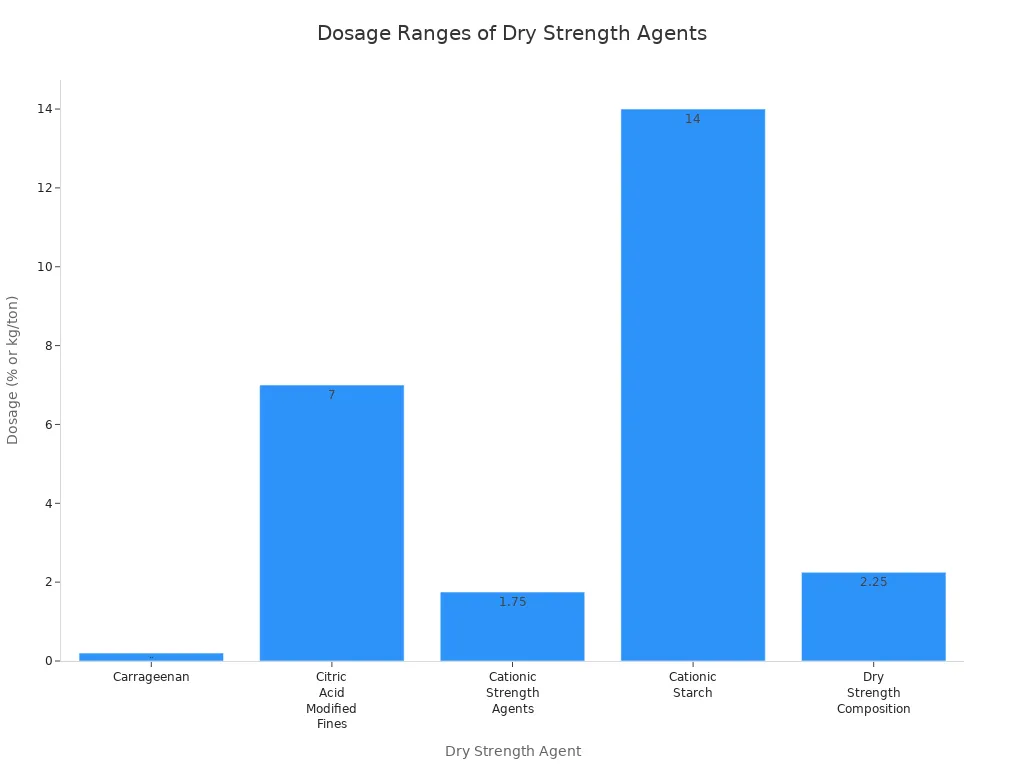

Selecting the right dosage for strength additives requires careful attention. You must consider the type of agent, fiber quality, and desired paper properties. For example, studies show that a 7% dosage of citric acid modified fines delivers the highest improvement in tensile, burst, and folding endurance. Cationic starch typically works best between 10 and 18 kg per ton of dry stock, while synthetic cationic agents perform well at 0.5 to 3 kg per ton. The table below summarizes common dosage ranges:

| Dry Strength Agent | Recommended Dosage Range | Notes |

|---|---|---|

|

Carrageenan |

0.2% (with 0.6% Al₂(SO₄)₃) |

Used with aluminum sulfate and CPAM for strength and filler retention. |

|

Citric Acid Modified Fines |

7% |

Maximizes tensile, burst, and folding endurance. |

|

Cationic Strength Agents |

0.5 – 3 kg/ton dry stock |

Includes polyamidoamine-epichlorohydrin, cationic acrylamide polymers. |

|

Cationic Starch |

3 – 20 kg/ton (preferably 10-18) |

Higher dosage preferred for optimal results. |

|

Dry Strength Composition |

0.5 – 4 kg/ton (preferably 1-3) |

Dosage adjusted for zeta potential and paperboard type. |

Compatibility with other papermaking additives is essential. You benefit from agents with nonionic or amphoteric properties, as these minimize interference from ions in the system. This compatibility improves retention, drainage, and overall paper strength. Agents with both anionic and cationic groups work synergistically with other additives, optimizing fiber bonding and process efficiency.

Common Challenges

You may encounter several challenges when using strength additives:

- Excessive strength can reduce softness and bulk, which is not ideal for tissue or specialty grades.

- Dosage inconsistencies, fiber variability, and changes in wet-end additives can cause strength fluctuations.

- Overdosing cationic starch (above 1–1.5%) may lead to foaming and unretained starch in solution.

- Starch additives can degrade biologically, causing foul odors and pH shifts.

- Maximizing tensile strength sometimes reduces compression or stiffness, making balance difficult.

- Process factors like refining, retention, and wet-press loading affect performance.

- Retrogradation in unmodified starches can impair results.

- When cationic starch alone is insufficient, you may need to use microparticle or synthetic polymers.

- Excessive strength may require you to reduce refining or chemical dosage to maintain desired properties.

Tip: New solutions such as enzyme-modified agents, nano-enhanced polymers, and on-site additive generation help you overcome these challenges. These innovations improve bonding, reduce energy use, and support sustainability goals.

You play a key role in producing high-quality paper when you select the right dry strength agent. These additives improve tensile, burst, and internal bond strength, letting you use recycled or lower-quality fibers without sacrificing performance.

- They help you reduce fiber costs and maintain consistent product strength.

- You also support sustainability by choosing bio-based or biodegradable options, which meet growing environmental demands.

Remember: Always evaluate fiber characteristics, refining, and compatibility with other additives to optimize results. The global trend toward lighter, stronger, and greener paper makes your choice of dry strength agent more important than ever.

FAQ

What is the difference between dry and wet strength agents?

You use dry strength agents to improve paper strength when dry. Wet strength agents help paper resist breaking when wet. Both serve different roles in papermaking. You select the right agent based on your product’s end use.

Can you use dry strength agents with recycled fibers?

Yes, you can. Dry strength agents work well with recycled fibers. They help you restore lost bonding ability and improve the quality of recycled paper. You often see better strength and runnability in recycled grades.

Are dry strength agents safe for food packaging?

Most natural dry strength agents, such as cationic starch, meet food safety standards. You should always check regulatory approvals for your specific application. Synthetic agents may require additional review for food contact.

How do you choose the right dry strength agent?

You consider fiber type, paper grade, and desired properties. You test different agents and dosages to find the best fit. You also evaluate cost, sustainability, and compatibility with other additives.