Retention aids help you optimize fiber and filler retention, which leads to lower chemical costs and improved paper formation. You see direct benefits in your process efficiency and sheet quality. When you use these solutions, you reduce fiber and filler losses, minimize chemical waste, and achieve better dewatering. For example, papermakers find that the efficiency of cationic polyacrylamide drops by about 12% in MBRW due to higher anionic trash and conductivity, as shown below:

| Water Source | Impact on cationic polyacrylamide efficiency |

|---|---|

| Fresh Water | N/A |

| UFW | N/A |

| MBRW | Reduced by approximately 12% |

You gain higher productivity and stronger, more uniform paper with the right retention aids.

Key Takeaways

- Retention aids help you keep more fibers and fillers in your paper, reducing waste and lowering chemical costs.

- Using retention aids improves paper strength and quality, leading to higher productivity and fewer production issues.

- Optimizing your retention system can enhance drainage and white water quality, supporting eco-friendly manufacturing practices.

- Choosing the right retention aid, like dual polymer systems, can maximize efficiency and reduce overall chemical usage.

- Implementing retention aids can lead to significant cost savings and improved operational efficiency in your paper production process.

Introduction: The Cost Challenge in Paper Production

Rising material prices and chemical consumption pressures

You face a challenging landscape in the paper industry. Material prices continue to rise, and chemical consumption grows each year. Several factors drive these trends:

- The global paper chemicals market is projected to increase from USD 35.01 billion in 2024 to USD 51.13 billion by 2032, with a CAGR of 4.3%.

- Advancements in manufacturing and higher demand for packaging and tissue papers push chemical usage upward.

- Innovations in chemical formulations and stricter environmental regulations shape your purchasing decisions.

- The demand for sustainable packaging leads to new, eco-friendly paper chemicals.

- Consumers now expect biodegradable and recyclable products, which reduces reliance on harmful additives.

- Global regulations favor sustainable materials, encouraging innovation to improve recyclability and lower carbon footprints.

You also see rising costs for wood pulp and energy. Supply chain disruptions and transportation expenses add to your financial pressures. Fluctuating energy prices can quickly impact your bottom line. As a result, you must find ways to manage these costs without sacrificing product quality.

Why optimizing chemical systems is key to profitability

You cannot ignore the impact of chemical costs on your profitability. When chemical prices rise, your raw material expenses increase. This situation squeezes your profit margins. You must decide whether to absorb these costs or pass them on to your customers, which can reduce demand if prices climb too high.

Optimizing your chemical systems offers a practical solution. For example, energy system optimization in tissue papermaking has reduced drying costs by 8.72%. This kind of improvement directly boosts your profitability. Retention aids play a crucial role in this process. They help you use chemicals more efficiently, reduce waste, and maintain high product quality. By focusing on system optimization, you position your operation for long-term success in a competitive market.

The Role of Retention Aids in Papermaking

How retention aids improve filler and fines retention

You rely on retention aids to keep valuable fibers and fillers in your paper sheet during production. These chemicals help you reduce material loss and control costs. When you add retention aids, you improve the efficiency of your process and maintain the quality of your final product.

- Retention aids enhance the retention of fillers and fines, which means less material escapes into the white water system.

- You keep more cellulose and wood pulp in the sheet, which supports consistent paper strength.

- The use of retention and drainage chemicals helps you minimize pollution and improve the uniformity of your paper.

You see a direct impact on filler retention rates. For example, TiO2 particles show first-pass retention rates of 50-60% in commercial plants when you use retention aids. Neutral filler particles stay in the sheet, while negatively charged particles need higher polyelectrolyte concentrations for better retention. This control allows you to optimize your chemical usage and reduce waste.

The connection between retention, formation, and drainage

Retention aids do more than just keep fibers and fillers in the sheet. You also improve formation and drainage on your paper machine. When you add acrylamide copolymers late in the process, you optimize the retention of fine particles. You balance colloidal charge by introducing oppositely charged materials, especially when you use dry-strength agents. PAC products help you manage pH levels and reduce problems with barium compounds in the pulp.

Tip: High retention benefits you when using ASA size or rosin emulsion size, as it prevents decomposition and supports sheet integrity.

You must avoid overdosing retention aids, since this can cause flocculation and reduce sheet quality. When you achieve the right balance, you enhance drainage rates and keep your machine clean. In tissue manufacturing, better retention of fines leads to higher machine efficiency and lower operational costs. You notice that wet-end chemistry affects dry-end performance, and retention aids play a key role in this connection.

How Better Retention Lowers Production Costs

Reducing fiber and filler losses

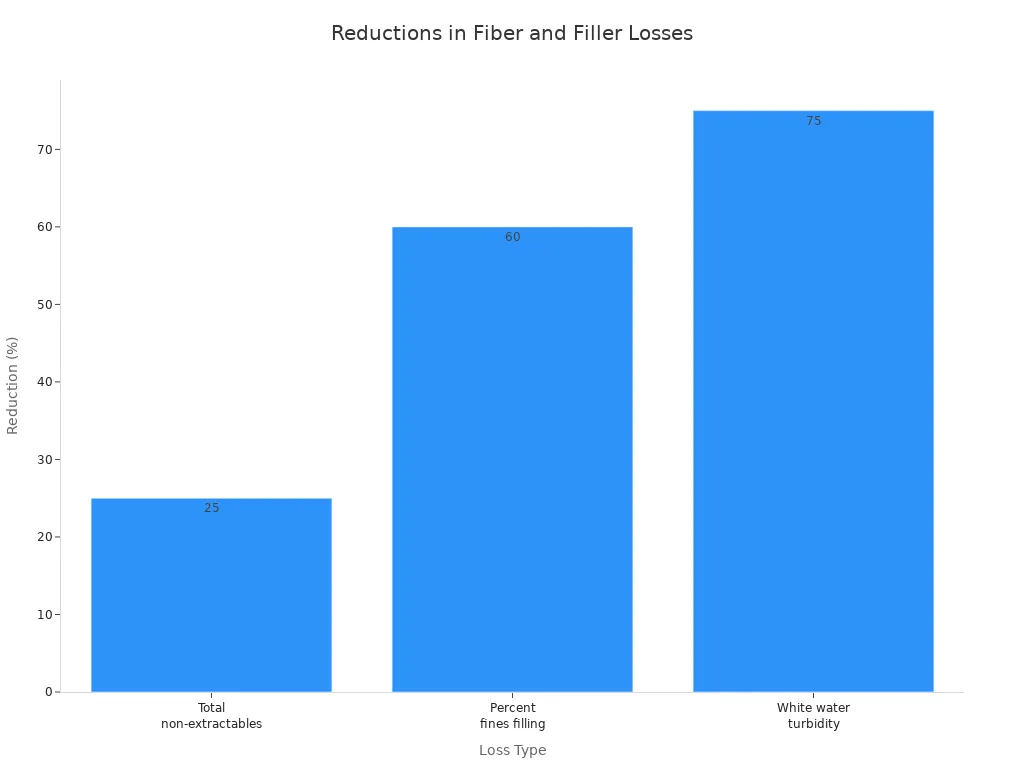

You can significantly cut your production costs by reducing fiber and filler losses. When you use retention aids, you keep more valuable materials in the paper sheet and send less to waste. This improvement not only saves raw materials but also boosts your overall process efficiency. The following table shows the impact of retention aids on key loss indicators:

| Evidence Description | Result |

|---|---|

| Reduction in total non-extractables after retention aid implementation | 25% decrease |

| Reduction in percent fines filling | 60% decrease |

| Reduction in white water turbidity | 75% decrease |

| Improvement in fiber fines retention | Significant |

| Improvement in felt performance and process reliability | Significant |

You see fewer losses and a cleaner process, which leads to better resource utilization and lower costs.

Minimizing chemical waste and improving white water quality

Retention aids help you minimize chemical waste and improve the quality of your white water. When you retain more fine fibers and fillers, you use fewer additives and keep your system cleaner.

- You enhance the retention of fine fibers and fillers, which reduces chemical waste.

- You optimize drainage, leading to improved white water quality.

- You lower the overall consumption of additives, making your white water system cleaner.

- You accelerate drainage, which improves machine speed and operational efficiency.

- You maintain the quality of your paper by improving the retention rate of fillers and fines.

You also support environmental goals by reducing effluent load and chemical consumption. This approach aligns with global trends toward eco-friendly manufacturing.

Enhancing paper strength and machine runnability

You improve both paper strength and machine runnability when you use retention aids effectively.

- You increase the retention of fibers, fines, and fillers, which strengthens the paper and improves its structure.

- You boost machine speed and runnability, which reduces operational issues and downtime.

- You enhance drainage and keep white water clean, which leads to higher production and yield with less energy.

- You control pitch and stickies, preventing web breaks and defects.

- You benefit from a cleaner process, which improves efficiency and product quality.

Tip: A well-optimized retention system leads to fewer breaks, better dewatering, and more consistent production.

Choosing the Right Retention System

Single vs. dual polymer systems

You face a critical decision when selecting between single and dual polymer retention systems. Each approach offers unique advantages for your papermaking process.

- Dual polymer systems often deliver higher retention rates while lowering your overall chemical costs.

- You benefit from robust floc structures in dual systems, which resist shear forces during papermaking.

- Dual systems improve dewatering, especially with activated sludge, and increase solids content in dewatered sludge.

- You experience less blinding of filter media with dual polymer conditioning.

- In single systems, you achieve optimal results with low and high charged cationic polyacrylamides (C-PAMs).

- Dual systems work best with high charged C-PAMs and anionic polyacrylamides (A-PAMs).

- Monitoring flocculation helps you optimize chemical dosages and improve separation efficiency.

Choosing the right system depends on your process needs and the specific challenges you encounter.

Synergy between Polyacrylamide (PAM) and PolyDADMAC

Combining Polyacrylamide (PAM) and PolyDADMAC creates a powerful synergy in your retention program. The table below highlights how these two chemicals work together:

| Evidence Description | Findings |

|---|---|

| PolyDADMAC destabilizes negatively charged particles | This leads to the formation of microflocs. |

| PAM increases the size of flocs | PAM creates bridges between particles, enhancing floc size. |

| Study by Zang et al. | Increasing positive charge improves flocculation efficiency. |

| Lee’s observation | Excessive PAM can reduce flocculation efficiency due to conformational changes. |

You achieve better retention and drainage by leveraging the strengths of both polymers. However, you must avoid overdosing PAM, as this can reduce flocculation efficiency.

Amazon Chemicals’ Retention Aid Solutions

Azfc® PAM and PolyDADMAC – high-efficiency retention aids

You want to maximize efficiency and quality in your papermaking process. Amazon Chemicals offers Azfc® PAM and PolyDADMAC, two high-performance solutions designed for modern paper mills. These retention aids deliver strong results by improving the retention of fibers, fines, and fillers. You see faster drainage and cleaner white water, which leads to higher machine speeds and less downtime.

Recent advancements in retention aid chemistry, such as the introduction of spherical polyelectrolyte brushes (SPBs), have set new standards for efficiency. These innovations allow you to achieve better retention of fine particles and improved runnability.

You benefit from the synergy between Azfc® PAM and PolyDADMAC. PolyDADMAC destabilizes negatively charged particles, while Azfc® PAM bridges them into larger, more stable flocs. This combination increases retention and enhances the quality of your finished paper.

Tailored formulations for different pulp and filler systems

You face unique challenges depending on your pulp and filler mix. Amazon Chemicals provides tailored retention aid formulations to address your specific needs. These solutions help you:

- Improve drainage and increase retention of fine particles.

- Boost productivity by increasing machine speed and fines retention.

- Reduce the environmental impact of water reuse.

| Functionality | Description |

|---|---|

| Accelerate drainage | Increases machine speed |

| Improved retention | Enhances retention of fines and fillers |

| Reduced wet-end additives | Lowers the need for additional chemicals |

| Improved machine runnability | Enhances overall efficiency |

| Increased brightness | Improves the quality of the paper |

| Cleaner white water system | Reduces environmental impact |

| Reduced downtime | Minimizes maintenance needs |

- Retention aids improve retention of fiber, fine, and filler across a wide pH range.

- You enhance runnability and productivity by improving drainage in the forming section.

The latest innovations in retention aid chemistry have helped reduce production costs and increase profitability for manufacturers like you.

When you choose Amazon Chemicals, you gain access to advanced solutions and expert support. You can optimize your process, improve paper quality, and meet your sustainability goals.

You achieve measurable cost savings and improved paper formation when you implement retention aids in your process. Real-world case studies show reduced broke levels, higher productivity, and better paper quality across global mills:

| Case Study | Solution | Results |

|---|---|---|

| Mondi Štětí Mill | CMC in wet-end chemistry | 30% reduction in broke levels, improved formation |

| India’s Largest Specialty Paper Manufacturer | Retention and drainage aids | Lower raw material costs, increased machine speed |

Retention aids also support sustainability by optimizing water usage and reducing waste. You enhance operational efficiency, strengthen paper, and promote recyclability. Consider retention aids as a strategic solution for sustainable, high-quality paper production.

FAQ

What are retention aids, and why do you need them?

Retention aids are specialty chemicals that help you keep fibers, fillers, and fines in the paper sheet during production. You use them to reduce material loss, improve sheet quality, and lower chemical costs.

How do retention aids help you save on chemical costs?

You use fewer additives when retention aids increase the efficiency of fiber and filler retention. This reduces waste and lowers your overall chemical consumption, which leads to direct cost savings.

Can you use retention aids with recycled fibers?

Yes, you can. Retention aids work well with recycled fibers. They help you manage higher levels of contaminants and improve sheet formation, even when you use recycled pulp.

How do you choose the right retention aid for your process?

You should consider your pulp type, filler system, and paper grade. Test different formulations and monitor performance. Consult with your chemical supplier for tailored recommendations.