You rely on oil-resistant coatings to keep paper packaging strong and clean when handling foods like burgers, pastries, or fried snacks. These specialized layers prevent oil and grease from soaking through, preserving both product quality and appearance. The global market for this type of packaging reached about $12.5 billion in 2023 and could grow to nearly $20 billion by 2032. Over the past five years, you have seen a surge in sustainable options, driven by stricter regulations, consumer demand, and new biodegradable materials.

Key Takeaways

- Oil-resistant coatings keep paper packaging clean and strong, preventing leaks from greasy foods.

- Fluorine-free coatings are safer for food contact and better for the environment, supporting recycling efforts.

- Choosing sustainable packaging helps reduce waste and supports a circular economy, benefiting the planet.

- Innovative coatings, like hybrid formulations, combine strength and oil resistance for better performance.

- Stay informed about regulations on PFAS to ensure your packaging choices are safe and compliant.

Introduction: The Demand for Oil-Resistant Paper Packaging

The rise of paper-based food packaging as a plastic alternative

You see paper-based packaging everywhere, from sandwich wraps to bakery boxes. Many companies now choose paper over plastic to reduce environmental impact. This shift comes as you and other consumers demand eco-friendly solutions. Restaurants, grocery stores, and food delivery services rely on paper packaging to meet sustainability goals. You benefit from packaging that feels natural and supports recycling efforts.

Why oil and grease resistance is critical for modern packaging

You expect your food packaging to stay strong and clean, even with oily or greasy foods. Oil-resistant coatings help prevent leaks and stains, keeping your hands and surfaces mess-free. Several factors drive the need for these coatings:

- You buy more packaged and processed foods, especially ready-to-eat meals and fried snacks.

- E-commerce and home delivery services require packaging that can handle transport without leaking.

- New coating materials, such as biodegradable wax and polymer blends, improve durability.

- The cosmetics and personal care industry needs packaging that prevents oil-based product leaks.

- Industrial sectors, including automotive and chemicals, use oil-resistant packaging for safe transport.

Challenges in balancing barrier performance with recyclability

You want packaging that protects your food but also supports recycling. Achieving both goals presents technical challenges:

- Effective barriers against oil and grease are essential for high performance.

- Traditional coatings, such as polyethylene or PFAS, make recycling difficult and harm the environment.

- The industry seeks sustainable alternatives that deliver oil resistance and work with recycling processes.

You play a role in driving demand for packaging that balances performance and sustainability. Companies continue to innovate, offering solutions that protect your food and the planet.

How Oil-Resistant Coatings Work

Mechanism of surface barrier formation against oil and grease

You rely on oil-resistant coatings to create a physical barrier that blocks oil and grease from penetrating paper packaging. The science behind this barrier involves several key principles:

- Oil moves through paper mainly by seeping into pores and defects, while water tends to absorb into the fibers.

- Carboxylate ions in certain coatings interact directly with water vapor, which improves water resistance.

- Thicker or double-layer coatings boost water barrier performance. When you add isopropyl alcohol (IPA) to the coating, it reduces porosity and defects, making it harder for oil to pass through.

These mechanisms help you keep food packaging clean and prevent leaks, even with oily foods.

Differences between internal sizing and surface coating approaches

You can choose between two main methods to achieve oil resistance in paper packaging. The table below outlines the differences:

| Method | Mechanism of Action | Oil Resistance Effectiveness |

|---|---|---|

| Internal Sizing | Adds materials to the slurry, making the paper hydrophobic or oil-resistant. | Develops resistance throughout the sheet. |

| Surface Sizing | Applies materials to the surface, filling capillaries and pores. | Makes water penetration more difficult, but not hydrophobic. |

Internal sizing changes the entire paper structure, while surface sizing targets only the outer layer. Your choice depends on the level of protection you need and the intended use of the packaging.

Importance of coating uniformity and curing in barrier performance

You achieve the best oil barrier when you apply the coating evenly across the paper surface. Studies show that a uniform layer, especially one containing lignin-rich cellulose nanofibrils, lowers surface energy and blocks oil more effectively than uneven coatings. Proper curing also matters. When you cure the coating correctly, you lock in its protective properties and ensure long-lasting performance. Consistency in application and curing helps you deliver reliable, high-quality oil-resistant packaging every time.

Types of Oil-Resistant Coatings Used in Paper Packaging

Fluorinated coatings (PFAS-based) — traditional but facing phase-out

You may recognize fluorinated coatings, often called PFAS-based, as the traditional choice for oil-resistant paper packaging. These coatings deliver strong oil and grease barriers, making them popular in fast food wrappers and microwave popcorn bags. However, you now see a global shift away from PFAS due to health and environmental concerns.

Regulatory agencies in North America and Europe have introduced strict rules. The U.S. EPA restricted long-chain PFAS in 2023, and the EU plans to ban all PFAS by 2025. States like California and Maine have already enacted bans on PFAS in consumer products.

You need to consider these changes when selecting packaging materials, as manufacturers move quickly to adopt safer alternatives.

Fluorine-free coatings — silicone, wax, and polymer-based systems

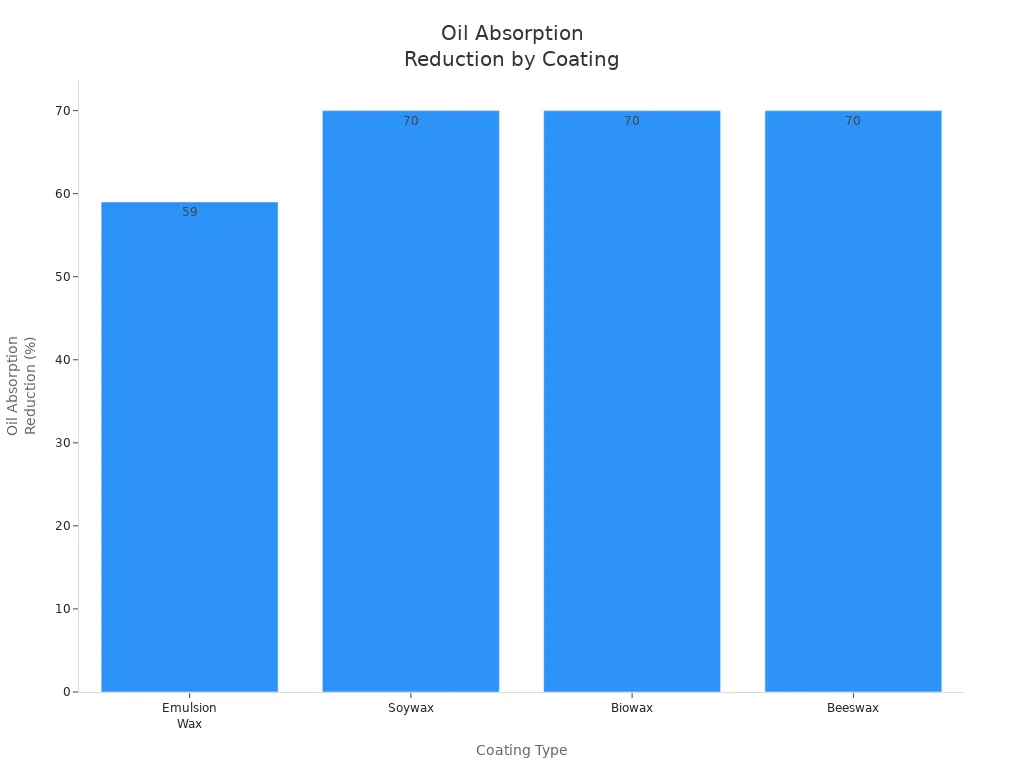

You can choose from a growing range of fluorine-free coatings, including silicone, wax, and polymer-based systems. These options offer effective oil resistance without the environmental risks of PFAS. Wax coatings, such as soywax, biowax, and beeswax, reduce oil absorption by up to 70%. Silicone-based waxes provide stability at high temperatures and resist degradation, making them suitable for food packaging.

| Coating Type | Oil Absorption Reduction |

|---|---|

| Emulsion Wax | ~59% |

| Soywax | ~70% |

| Biowax | ~70% |

| Beeswax | ~70% |

You benefit from these coatings because they support recyclability and biodegradability. Wax coatings also show excellent beading of vegetable oil, which means less mess and better product protection.

Hybrid formulations — combining mechanical strength and resistance

You may require packaging that not only resists oil but also stands up to physical stress. Hybrid formulations, such as epoxy/polyurethane (EP/PU) blends, combine the best features of different materials. These systems deliver enhanced tensile strength, improved flexibility, and superior chemical and UV resistance compared to single-component coatings.

| Feature | Hybrid Systems (EP/PU) | Single-Component Systems (PU) |

|---|---|---|

| Mechanical Properties | Enhanced tensile strength | Moderate tensile strength |

| Flexibility | Improved shape memory behavior | Limited flexibility |

| Chemical Resistance | Superior chemical resistance | Moderate chemical resistance |

| UV Resistance | Better UV stability due to hybridization | Poor UV resistance |

| Application Complexity | More complex application procedures | Simpler application |

| Cost | Generally higher due to material complexity | Lower cost |

You should weigh the benefits of hybrid coatings against their higher cost and more complex application. For demanding applications, these advanced oil-resistant coatings can provide the durability and performance you need.

Benefits of Fluorine-Free Oil-Resistant Coatings

Safe for direct food contact (PFAS-free compliance)

You want assurance that your food packaging is safe. Fluorine-free oil-resistant coatings meet strict safety standards for direct food contact. Many global certifications validate this safety. For example, Intertek’s PFAS Free Certification confirms the absence of PFAS in packaging. This certification relies on ISO 17025-accredited labs and supports transparency for manufacturers. You can also look for compliance with these standards:

| Certification/Standard | Region |

|---|---|

| EN13432 | EU |

| ASTM D6400 | US |

| BPI | N/A |

| LFGB | Germany |

| FSC | N/A |

These certifications help you identify packaging that aligns with evolving regulations and consumer expectations.

Environmentally friendly and easier to recycle

You care about the environmental impact of your packaging choices. Fluorine-free coatings support recycling and reduce harm to the environment. Unlike traditional fluorinated coatings, which complicate recycling and may introduce harmful chemicals, fluorine-free options use materials such as acrylate, chitosan, cellulose, and protein. These materials break down more easily and fit into existing recycling systems.

- Fluorine-free coatings are designed for compatibility with recycling processes.

- They help lower the environmental footprint of packaging.

- You support a circular economy by choosing packaging that is easier to recycle.

Tip: When you select packaging with fluorine-free oil-resistant coatings, you help reduce landfill waste and promote sustainable practices.

Maintains printability and paper flexibility

You expect packaging to look good and perform well. Fluorine-free coatings work with many paper grades and maintain the flexibility you need for folding, wrapping, and shaping. These coatings also enhance printability, so you get sharp graphics and clear branding.

- Fluorine-free coatings improve adhesion and release performance.

- Innovations in coating technology meet the needs of packaging and labeling industries.

- You benefit from packaging that remains attractive and functional.

Applications in Modern Packaging Industries

Food wrapping paper and take-out containers

You encounter oil-resistant coatings every time you pick up a burger, sandwich, or pastry from your favorite restaurant. These coatings keep grease from soaking through the paper, so your hands and surfaces stay clean. In the fast food industry, you see several types of coatings used to achieve this barrier:

- Polyethylene (PE) coatings line disposable coffee cups, preventing leaks.

- PE coatings also protect takeout boxes, keeping food fresh and packaging sturdy.

- Wax coatings, including soy and beeswax, appear in fast food wrappers and bakery papers.

These solutions help you enjoy your meal without worrying about mess or packaging failure.

Cup stock and liquid packaging board

You rely on sturdy cups and cartons for drinks and dairy products. Oil-resistant coatings play a vital role in these applications by preventing leaks and maintaining the strength of the packaging. The following table highlights how different coatings enhance performance:

| Coating Material | Functionality |

|---|---|

| Polyethylene (PE), aluminum foil | Provide liquid and oil resistance, prevent absorption and leakage. |

| Double-sided PE coating | Enhances barrier properties, prevents leakage from both sides. |

You benefit from these advanced materials because they keep your beverages contained and your packaging intact, even with hot or cold liquids.

Industrial and e-commerce packaging with oil barrier needs

You may not realize that oil-resistant coatings extend beyond food packaging. In industrial and e-commerce sectors, these coatings protect products during shipping and storage. Automotive parts, electronics, and cosmetics often require packaging that resists oil and grease. This barrier prevents contamination, preserves product quality, and reduces the risk of damage during transit. By choosing packaging with oil-resistant coatings, you ensure that goods arrive in excellent condition, ready for use or sale.

Amazon Chemicals’ Oil-Resistant Coating Solutions

Azfc® Oil-Resistant Coating — fluorine-free, high-efficiency barrier agents

You need packaging that delivers reliable protection against oil and water. Azfc® Oil-Resistant Coating stands out among fluorine-free solutions. This advanced coating achieves high repellency by maintaining large contact angles for both water and oil. You benefit from a product that meets strict PFAS regulations, ensuring safety for food contact and environmental compliance. Azfc® also offers high visible light transmittance, making it suitable for packaging that requires transparency. You experience smooth sliding performance due to its low friction properties, even in demanding conditions. The coating maintains its barrier function after exposure to temperatures up to 300°C. You can apply Azfc® to a wide range of substrates, including glass and metals.

| Feature | Description |

|---|---|

| Water and oil repellency | Achieves high water and oil repellency by maintaining large contact angles for both water and oil. |

| Compliance with PFAS regulations | Does not contain fluorine, making it compliant with PFAS regulations and environmentally safe. |

| High visible light transmittance | Offers high visible light transmittance, suitable for applications requiring transparency. |

| Low friction | Reduces the coefficient of friction for smooth sliding performance in harsh conditions. |

| High heat resistance | Maintains water and oil repellency even after prolonged exposure to 300°C. |

| Compatibility with various substrates | Applicable to a variety of substrates, including glass, metals, and other materials. |

Tip: When you choose Azfc®, you invest in a coating that combines safety, performance, and versatility.

Compatible with alkaline papermaking systems

You often work with alkaline papermaking systems to produce packaging that meets modern standards. Azfc® Oil-Resistant Coating integrates seamlessly with these systems. You avoid complications during production because the coating does not interfere with the alkaline process. This compatibility helps you maintain consistent quality and efficiency in your operations. You can rely on Azfc® to deliver strong oil and water resistance without compromising the integrity of your paper products.

Designed for both internal and surface application processes

You require flexibility in how you apply oil-resistant coatings. Azfc® adapts to both internal and surface application methods. You can add the coating during the papermaking process for internal sizing, which builds resistance throughout the paper sheet. You may also apply it as a surface coating, targeting the outer layer for enhanced barrier performance. This dual capability allows you to customize your packaging to meet specific needs, whether you prioritize durability, appearance, or recyclability.

Toward a Sustainable and Safer Packaging Future

Transitioning from PFAS to green alternatives

You face a changing landscape in packaging technology. The move away from PFAS-based coatings brings both challenges and opportunities. You must develop new solutions that match the performance of traditional coatings in lubrication, adhesion, and durability. The engineering process requires you to test materials for sterilization compatibility and long-term reliability. You also consider the economic impact, as new coatings often cost more to develop and implement. Regulatory pressures push you to find safer options, but these rules also encourage innovation. Advances in materials science, such as biopolymer coatings and graphene, open new doors for effective oil-resistant coatings. You have the chance to lead the industry by adopting safer, high-performance alternatives.

- You must solve scientific and engineering problems to maintain barrier performance.

- You manage higher costs and adjust production timelines for new materials.

- You respond to stricter regulations that drive the search for safer coatings.

- You explore innovative materials that offer better safety and sustainability.

Tip: By embracing green alternatives, you position your business as a leader in responsible packaging.

Supporting circular economy and eco-friendly paper production

You play a key role in building a circular economy through your packaging choices. Compostable coatings break down naturally, returning nutrients to the soil and reducing harmful residues. You help divert materials from landfills to composting facilities, supporting sustainable waste management. Oil-resistant coatings made from natural materials reduce your reliance on petroleum-based products. You improve the mechanical properties of packaging, which increases durability and extends product life. By choosing eco-friendly coatings, you support the repurposing of materials and align with sustainability principles.

- Compostable coatings support soil health and minimize waste.

- You help shift packaging from landfill disposal to composting and recycling.

- Natural coatings enhance grease resistance and durability.

- You contribute to a system where materials are reused, not discarded.

🌱 When you select sustainable coatings, you help create a cleaner environment and a stronger future for packaging.

You help shape a safer and more sustainable future by choosing oil-resistant coatings for paper packaging. These solutions keep food fresh and uncontaminated while supporting recycling and composting efforts. Recent advances include starch-based and ceramic coatings that improve barrier performance and biodegradability.

Industry experts predict strong growth in eco-friendly packaging as demand rises across food, pharmaceutical, and personal care sectors.

| Trend | Description |

|---|---|

| Biodegradable Materials | Materials that break down naturally, reducing environmental impact. |

| High-Performance Coatings | Innovations that enhance durability and effectiveness. |

| Circular Economy Practices | Focus on recycling and resource efficiency. |

FAQ

What makes oil-resistant coatings safe for food packaging?

You choose coatings that meet strict food safety standards. Manufacturers test these coatings for chemical migration and toxicity. Certifications like FDA, BPI, and LFGB confirm safety for direct food contact. You can trust these products to protect your food without harmful substances.

Can you recycle paper packaging with oil-resistant coatings?

You can recycle most fluorine-free coated papers. These coatings use materials like wax, starch, or biopolymers, which break down during recycling. Always check local recycling guidelines. Some regions accept only specific coatings, so you should verify before disposal.

How do you apply oil-resistant coatings to paper?

You can apply coatings during papermaking (internal sizing) or after production (surface coating). Surface coating uses rollers or spray systems for even coverage. Internal sizing mixes the agent into the pulp. Both methods improve oil resistance and maintain paper strength.

Do oil-resistant coatings affect print quality?

You get excellent print results with most modern coatings. Manufacturers design these coatings to support ink adhesion and color vibrancy. You can print logos, text, and graphics clearly, ensuring your packaging looks professional and attractive.

Are oil-resistant coatings biodegradable?

You find many biodegradable options today. Coatings made from natural waxes, starches, or proteins break down in composting environments. You help reduce landfill waste by choosing biodegradable coatings for your packaging.