You encounter Optical Brightening Agents in many types of paper you use daily. These specialized chemicals absorb ultraviolet light and release it as visible blue light, which makes paper appear brighter and whiter. You benefit from this process because it creates crisp, clean-looking pages without expensive bleaching. > Many industries rely on OBAs for their cost-effectiveness and ability to enhance visual appeal.

Key Takeaways

- Optical Brightening Agents (OBAs) make paper look brighter and whiter by absorbing UV light and emitting blue light, enhancing visual appeal without harsh bleaching.

- Using OBAs is a cost-effective way to improve paper brightness, reducing the need for excessive bleaching and lowering environmental impact.

- OBAs work best in specific conditions, such as proper pH levels and with compatible sizing agents, ensuring optimal performance in paper production.

- Papers treated with OBAs resist yellowing and maintain their brightness over time, making them ideal for high-quality printing and specialty applications.

- Choosing paper with OBAs enhances the overall quality of printed materials, making them more vibrant and visually appealing.

Introduction — What Are Optical Brightening Agents?

Definition and basic working principle of OBAs.

You often see paper that looks bright and clean, but you may not realize what makes it so appealing. Optical Brightening Agents play a key role in this transformation. These are specialized chemicals that absorb invisible ultraviolet (UV) light and re-emit it as visible blue light. This process, called fluorescence, tricks your eyes into seeing the paper as whiter and brighter than it actually is. You benefit from this effect every time you use high-quality copy paper or read a glossy magazine.

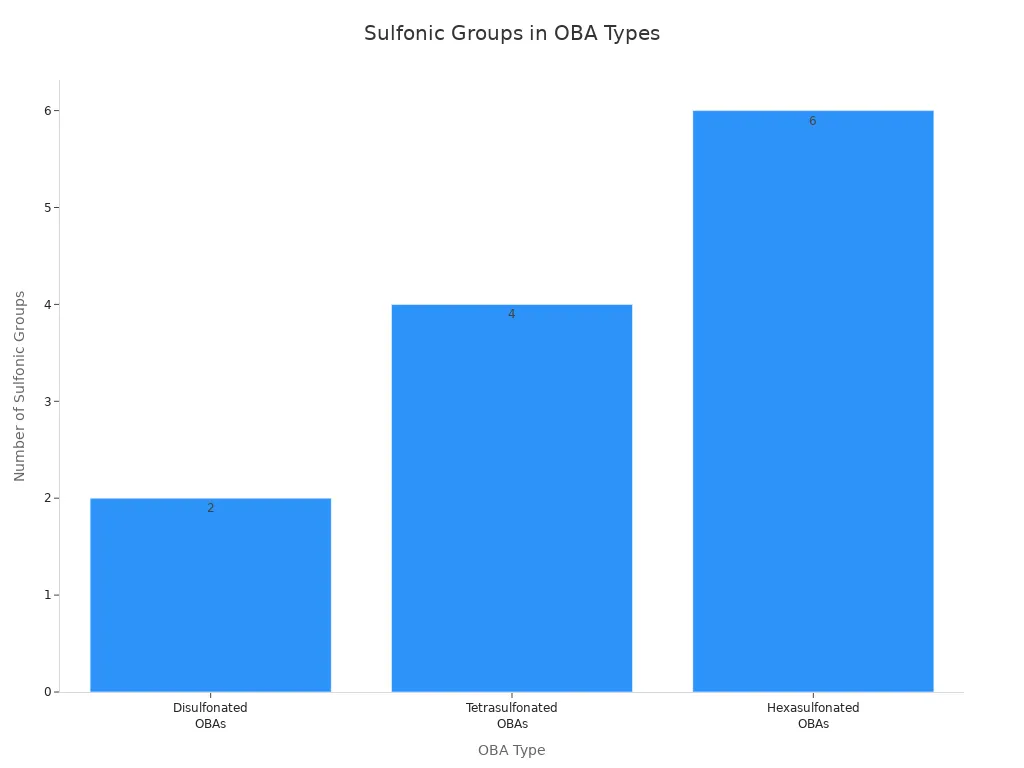

Optical Brightening Agents come in several chemical classes, each designed for specific stages in papermaking. The table below shows the most common types and their properties:

| Type of OBA | Number of Sulfonic Groups | Affinity | Solubility | Usage Area |

|---|---|---|---|---|

| Disulfonated OBAs | 2 | Hydrophobic | Low | Wet end |

| Tetrasulfonated OBAs | 4 | Medium | Good | Wet and dry end |

| Hexasulfonated OBAs | 6 | Excellent | High | Dry end (coating) |

Why OBAs are essential for improving paper appearance and whiteness.

You want paper that looks crisp and professional. Optical Brightening Agents help you achieve this goal without relying on harsh bleaching methods. Traditional bleaching, such as hydrogen peroxide, removes impurities but can leave the paper looking dull. OBAs, on the other hand, enhance whiteness by adding a blue tint that neutralizes yellow shades. This makes the paper appear cleaner and more vibrant.

| Comparing Item | Hydrogen Peroxide Bleaching | Optical Brightening Agent |

|---|---|---|

| Principle | Removes natural impurities and pigment | Absorb UV-light→Emit blue light→Visual whitening |

| Changes fiber color? | Yes | No |

| Whiteness effect | High, but a little dull | Brightly white, strong cleanliness |

| Yellowing control | Limit, fades easily over time | Good, can neutralize the slightly yellow color shade |

| Applicable stage | Pretreatment bleaching | After bleaching, finishing, and pretreatment for printing |

Note: You gain longer-lasting whiteness and better visual appeal when you choose paper treated with Optical Brightening Agents.

How Optical Brightening Agents Work

Fluorescence mechanism — absorbing UV light, emitting blue light.

You experience the magic of Optical Brightening Agents every time you see paper that looks extra white under sunlight or fluorescent lamps. These agents work through a process called fluorescence. When ultraviolet (UV) light hits the paper, the agents absorb this invisible energy and instantly re-emit it as visible blue light. This blue light masks any yellowish tint in the paper, making it appear brighter and whiter to your eyes.

| Aspect | Description |

|---|---|

| Mechanism | Absorption of UV light and re-emission as visible light |

| Purpose | Enhances brightness of paper |

| Analysis Method | Spectrofluorometer, spectrophotometer, image restoration microscope |

| Findings | Regression equations established between fluorescence intensity and optical effects |

- Optical Brightening Agents enhance paper brightness and alter color perception under different lighting.

- They absorb UV light and emit blue light, which compensates for yellowish hues.

- The effect depends on the amount of UV light present, so paper may look different under various light sources.

Tip: You may notice that paper treated with these agents looks especially white under sunlight, but less so under LED lighting with little UV content.

Interaction with cellulose fibers and surface coatings.

You benefit from the interaction between these agents and the cellulose fibers in paper. The effectiveness of the brightening process depends on how well the agents attach to the fibers. Several factors influence this interaction:

| Mechanism/Factor | Description |

|---|---|

| Polarity of cellulose surface | Influences the adsorption of agents on cellulose fibers. |

| Solubility of the agent | Affects how well the agent can interact with cellulose. |

| Ionic strength during adsorption | Varies the effectiveness of agent adsorption on cellulose. |

| Presence of bivalent cations (e.g., Ca2+) | Modifies the interaction dynamics between agents and cellulose fibers. |

Surface coatings also play a key role. When you use paper with coatings containing co-binders like starch or carboxymethyl cellulose (CMC), you get even higher whiteness. These co-binders work together with the agents, creating a synergistic effect that boosts both brightness and whiteness.

- Co-binders such as starch and CMC enhance the optical properties of the agents.

- Adjusting the dosage of agents in coatings can further increase the whiteness of the paper.

The role of pH and sizing in OBA performance.

You should know that the environment during papermaking affects how well these agents work. The pH level is especially important. Some agents, like Fluorescent Whitening Agent 210, maintain their effectiveness even in acidic conditions. This stability ensures that you get consistent whitening, even when the papermaking process involves low pH stages.

Sizing agents, which help control the paper’s absorbency, can sometimes block the action of brightening agents. If sizing agents remain on the fibers, they may prevent the agents from attaching properly, leading to uneven brightening. Proper pretreatment and careful control of sizing help you achieve the best results.

Note: For optimal brightness, papermakers must balance pH and sizing to allow the agents to perform at their peak.

Benefits of Using OBA in Paper Manufacturing

Enhanced brightness and whiteness.

You want your paper to look as bright and white as possible. Optical Brightening Agents help you achieve this by increasing the ISO brightness of paper. When you use aspen high-yield pulp, you typically see brightness levels between 84 and 85% ISO. Bleached hardwood kraft pulp can reach 88 to 90% ISO brightness. The difference comes from the amount of lignin in the pulp. High-yield pulp contains more lignin, which limits brightness. Bleached kraft pulp has almost no lignin, so Optical Brightening Agents work even better. You notice a clear improvement in whiteness, especially when you use high-quality printing or writing paper.

- Aspen high-yield pulp: 84–85% ISO brightness

- Bleached hardwood kraft pulp: 88–90% ISO brightness

- OBAs show greater effectiveness in bleached kraft pulp due to lower lignin content

Improved optical appeal and print contrast.

You expect your documents and printed images to stand out. Optical Brightening Agents absorb ultraviolet light and emit blue light, which neutralizes yellow tones in paper. This process gives your paper a “whiter-than-white” look. You see brighter, more vibrant images and sharper text. The enhanced brightness and vibrancy improve the visual appeal and print contrast of your finished products.

- OBAs absorb UV light and emit blue light, masking yellow tones

- You get a whiter appearance and improved print contrast

- Printed images appear more vibrant and visually appealing

- Manufacturers use OBAs to make paper products stand out

Tip: When you choose paper with OBAs, you ensure your printed materials look crisp and professional.

Cost-effective alternative to excessive bleaching.

You want to balance quality and cost in paper production. Optical Brightening Agents offer a smart solution. Instead of relying on extra bleaching, you can use OBAs to achieve high brightness with fewer resources. This approach saves you money and reduces environmental impact. The table below compares OBAs with traditional bleaching processes:

| Aspect | Optical Brightening Agents | Traditional Bleaching Processes |

|---|---|---|

| Resource Use | Lower | Higher |

| Production Efficiency | Streamlined | Extensive |

| Environmental Impact | Reduced mill effluents | Higher effluents |

| Chemical Costs | Lower | Higher |

| Pulp Yield | Higher | Lower |

You benefit from lower chemical costs, higher pulp yield, and a more sustainable manufacturing process.

Application Areas of OBA

Cultural papers (copy, printing, writing).

You interact with cultural papers every day, whether you print documents, write notes, or make copies. These papers rely on Optical Brightening Agents to achieve a clean, bright appearance. You see the greatest impact in photographic papers, especially fiber-based, gelatin silver types. Since the mid-1950s, manufacturers have added these agents to enhance the brightness and fluorescence of photographs under UV light. The use of these agents peaked in the early 1960s, making photos look more vivid and visually appealing. Over time, the industry shifted toward resin-coated papers, which led to a decline in their use. Today, you still benefit from their ability to improve the visual quality of printed and written materials.

- Photographic papers, especially fiber-based, gelatin silver types, use these agents for enhanced brightness.

- The peak usage occurred in the early 1960s, improving the visual appeal of photographs.

- You notice brighter, more vibrant documents and images in copy, printing, and writing papers.

Packaging board for visual clarity.

You expect packaging to look clean and attractive on store shelves. When manufacturers add Optical Brightening Agents to packaging board, you see a noticeable improvement in brightness and clarity. The combination of these agents with polyvinyl alcohol (PVA) further boosts both brightness and fluorescence. The table below shows how different combinations affect visual properties:

| Component | Brightness Improvement (units) | Fluorescence Improvement (units) |

|---|---|---|

| OB alone | 1.7 – 2.0 | 1.9 – 2.3 |

| OB + 1 pph PVA | 2.7 – 3.2 | 2.7 – 3.7 |

| OB + 2.0-2.5 pph PVA | 4.0 – 4.3 | 4.0 – 4.3 |

Tip: You get sharper graphics and more appealing packaging when these agents are used with PVA in the coating.

Specialty papers requiring high whiteness.

You may need specialty papers for applications that demand exceptional whiteness, such as security documents, high-end stationery, or premium labels. These papers must maintain their brightness over time and under various lighting conditions. By using Optical Brightening Agents, manufacturers ensure that specialty papers meet strict standards for whiteness and visual appeal. You benefit from documents that resist yellowing and maintain a crisp, professional look, even after extended use.

Amazon Chemicals’ OBA Solutions

High stability under alkaline conditions.

You need Optical Brightening Agents that perform reliably in modern papermaking environments. Amazon Chemicals designs its solutions for high stability under alkaline conditions. Many paper mills now use alkaline processes to improve paper strength and durability. When you choose Amazon Chemicals’ products, you get consistent brightening even when the pH rises. This stability means you avoid fluctuations in whiteness and brightness, which helps you maintain quality standards. You can trust these agents to deliver results in both the wet end and surface applications.

Note: High alkaline stability reduces the risk of fading or uneven color, especially in demanding production lines.

Low yellowing and excellent lightfastness.

You want your paper to stay bright and white over time. Amazon Chemicals’ Optical Brightening Agents offer low yellowing and excellent lightfastness. These properties ensure your paper resists discoloration, even after exposure to sunlight or artificial lighting. You benefit from documents, packaging, and specialty papers that keep their fresh appearance for longer periods. This feature is especially important for archival materials and high-value printed products.

- Low yellowing protects against aging and environmental effects.

- Excellent lightfastness keeps paper looking new, even under strong light.

Compatible with AKD/ASA systems and surface sizing.

You often work with advanced sizing systems like AKD (alkyl ketene dimer) and ASA (alkenyl succinic anhydride) to control paper absorbency. Amazon Chemicals’ solutions integrate smoothly with these systems. You do not face issues with uneven brightening or chemical interference. The agents also work well with surface sizing, so you can apply them at different stages of production.

| Feature | Benefit to You |

|---|---|

| AKD/ASA compatibility | Reliable performance in modern sizing systems |

| Surface sizing compatibility | Flexible application options |

| No negative interactions | Consistent optical quality |

Tip: You can streamline your process and achieve optimal brightness by using Amazon Chemicals’ Optical Brightening Agents with your preferred sizing technologies.

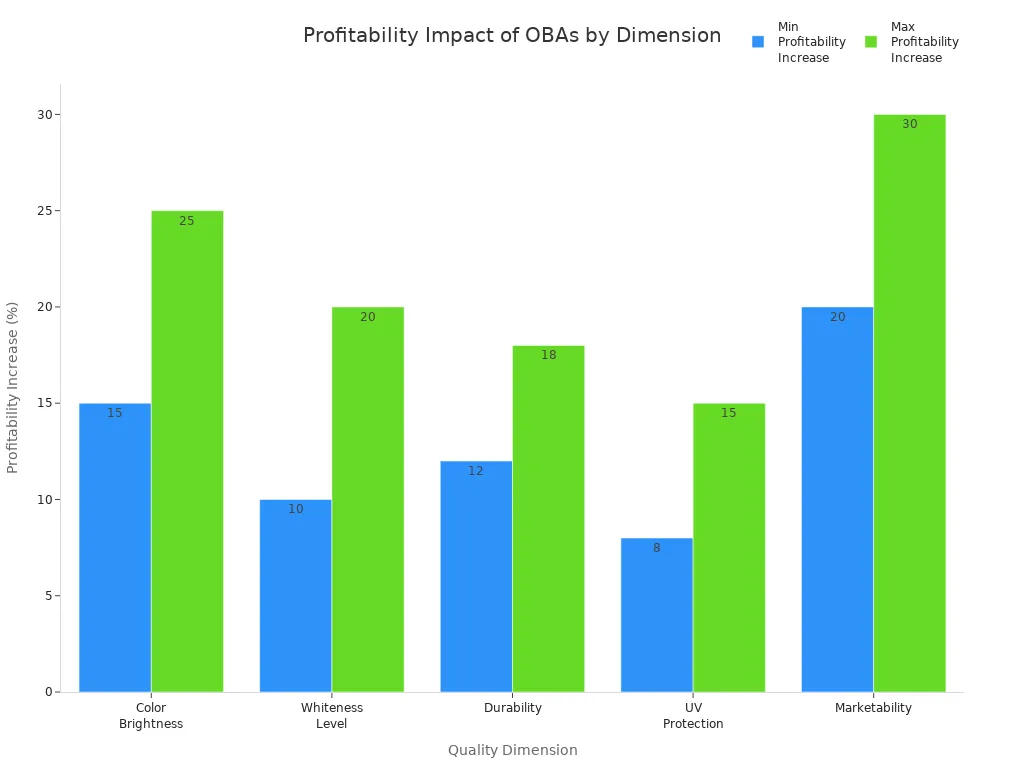

You see the impact of Optical Brightening Agents in every sheet of bright, white paper you use. These agents boost color brightness, whiteness, and durability, making paper products more appealing and profitable.

| Dimension | Impact on Quality | Profitability Increase (%) |

|---|---|---|

| Color Brightness | Improves visual appeal | 15-25 |

| Whiteness Level | Makes products appear fresher | 10-20 |

| Durability | Maintains quality over time | 12-18 |

| UV Protection | Prevents color degradation | 8-15 |

| Marketability | Attracts more customers | 20-30 |

You benefit from ongoing advancements, such as eco-friendly and biodegradable formulations, which support sustainability and meet changing consumer demands. When you evaluate paper quality, consider how these agents enhance both performance and environmental responsibility.

FAQ

What are Optical Brightening Agents made of?

You find most Optical Brightening Agents made from stilbene derivatives or similar organic compounds. Manufacturers design these chemicals to absorb ultraviolet light and emit visible blue light, which increases paper brightness and whiteness.

Do OBAs affect paper recyclability?

You can recycle paper with OBAs. Most recycling processes remove or dilute these agents. However, high concentrations may slightly affect the brightness of recycled paper. You should not worry about OBAs causing major recycling issues.

Are OBAs safe for everyday use?

You use paper with OBAs safely every day. Regulatory agencies approve these agents for common applications. Manufacturers test OBAs for toxicity and environmental impact before use in consumer products.

Can you see the effect of OBAs under all lighting?

You notice the whitening effect best under sunlight or fluorescent lights, which contain ultraviolet rays. Under LED lighting with little UV, the effect appears less pronounced. You may see a difference in brightness depending on the light source.